Please call us to find out about our services.

| CALL 609-321-5283 |

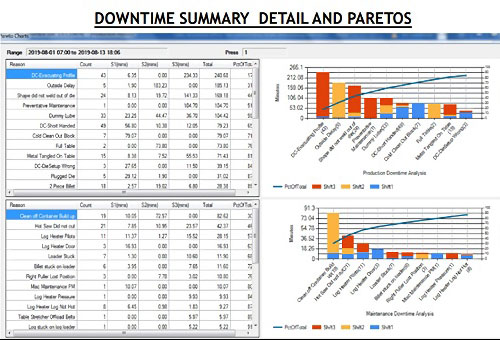

Aluminum Extrusion Process AnalysisFind out more |

Aluminum Extrusion Equipment EvaluationFind out more |

Aluminum Extrusion Die ManagementFind out more |

Aluminum Extrusion Employee TrainingFind out more |

JEL Enterprises provides the following services for aluminum extrusion companies:

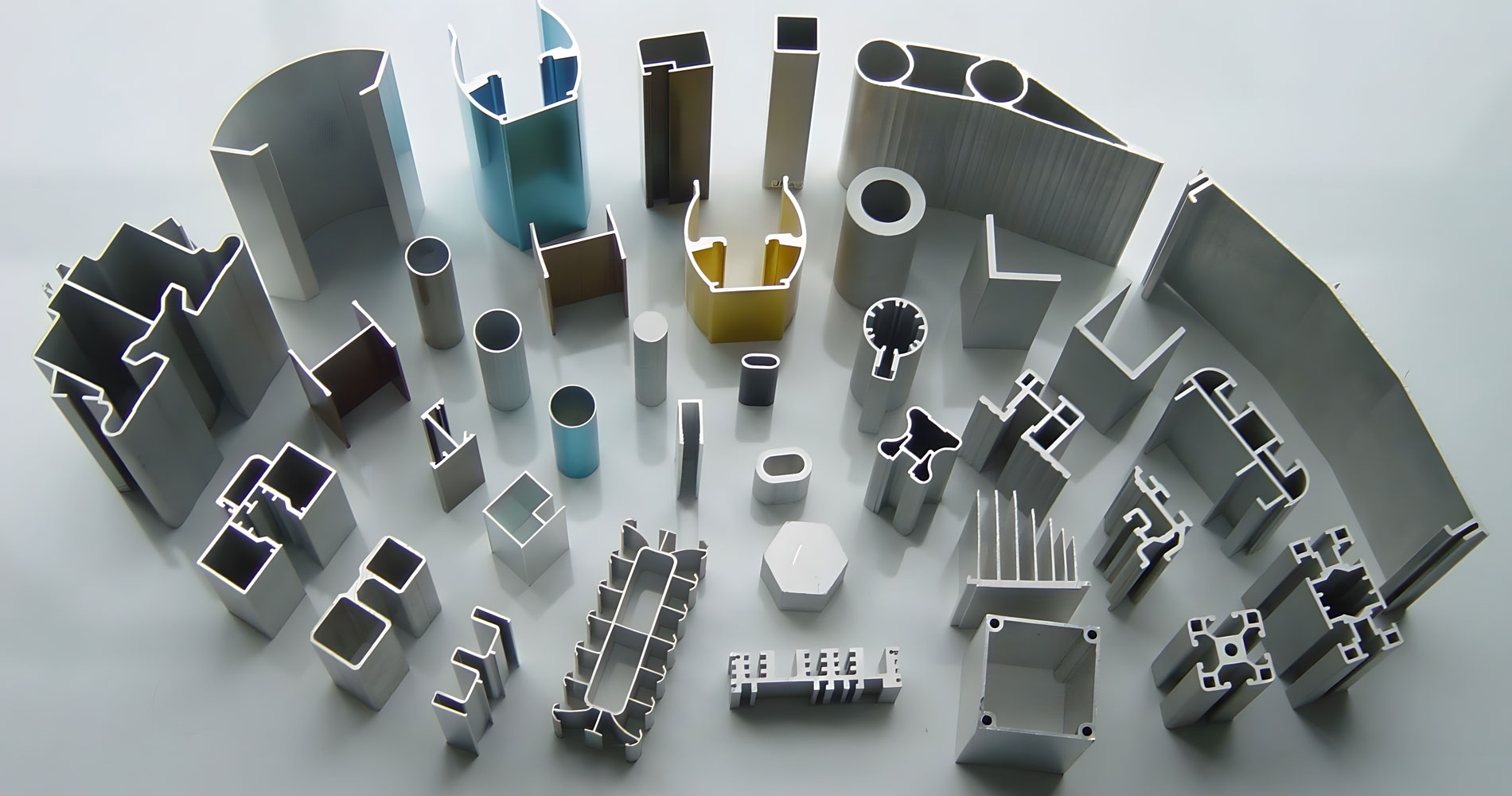

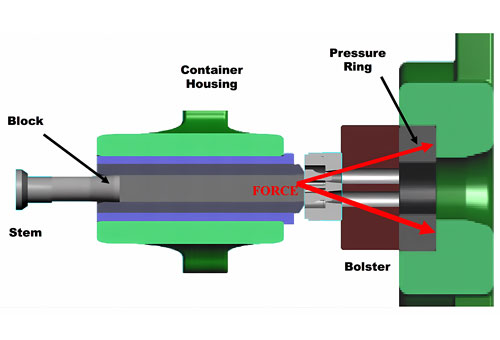

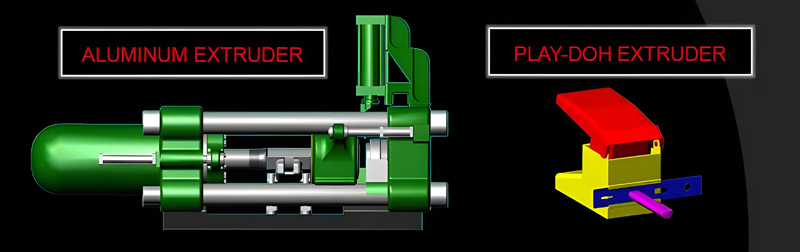

To understand aluminum extrusion, one must first comprehend the extrusion process. Extrusion is much like pushing Play-Doh through a Play-Doh extrusion toy which uses leverage to compress and force the Play-Doh through geometric orifices, producing an elongated shape.

The following video is the ideal aluminum extrusion process. Many extrusion operations do not reach the steady state optimum process due to issues with equipment, training, maintenance, dies and more.

Extrusion Process Video

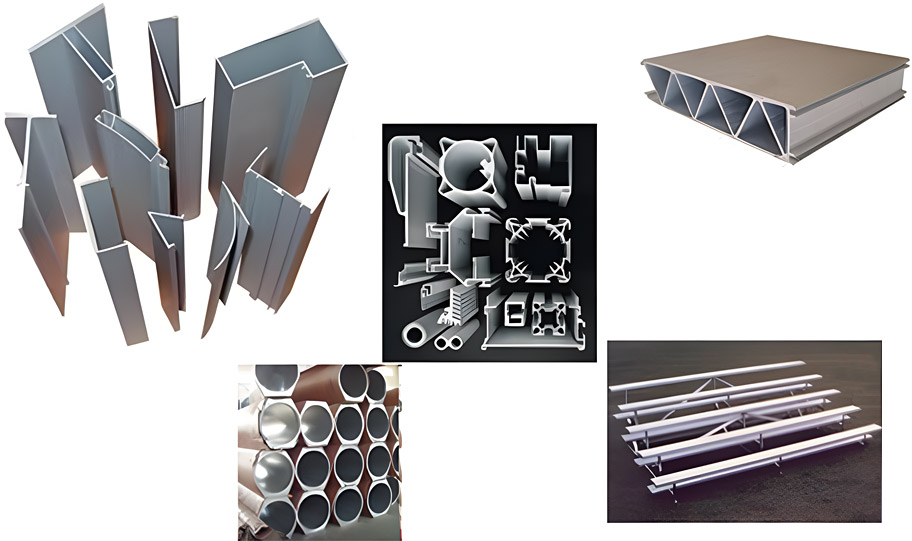

Aluminum extrusion is used more and more due its weight to strength ratio and enhanced mechanical properties compared to other processes. Bottom line, aluminum extrusion weight to strength, shorter lead times, and ability to produce near net shapes are all big advantages over other processes.

Jim graduated with a degree in Industrial Engineering. He has worked as Department Head (including P&L) and in Project/Process Engineering. Jim built his aluminum extrusion consulting business to help fill the training gap in extrusion operations, dies, maintenance and extrusion technology. Jim was instrumental in establishing a Green Field operation – equipment selection, installation, and then training on all aspects of extrusion to "green" employees who had no extrusion operation experience (but attitude and aptitude is a first step in employee selection). Jim has been involved in many aluminum extrusion plant and employee evaluations, modernization and retraining of employees. He has trained all levels of employees, from CEO and Plant Managers, to helpers off the shop floor.

Call JEL Enterprises at 609-321-5283, or email us, to find out how we can improve the productivity and profitability of your aluminum extrusion processes.