Please call us to find out about our services.

| CALL 609-321-5283 |

Questions you may want to ask are:

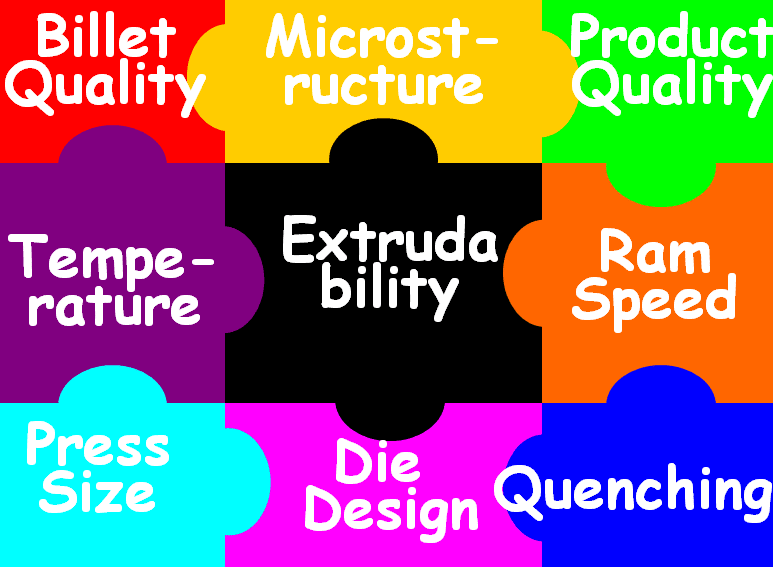

Using industry metrics we compare your aluminum extrusion plant with benchmarks and "like" equipment to find out where your operation is in relation to benchmark data from other aluminum extrusion companies in North Carolina and the rest of the country. Then we develop a plan of changes which can lead to incremental performance increases in the aluminum extrusion process for your North Carolina company.

This Benchmark Data chart assumes the aluminum extrusion presses at your North Carolina facility are older, and were installed before 2006:

| 2019 Aluminum Extrusion Benchmark Data | |||||

|---|---|---|---|---|---|

| 6" Press (1650 UST) | |||||

| 25% Percentile | Median | 75% Percentile | 90% Percentile | ||

| Recovery | 75.2% | 79.75 | 81.9% | 84.0% | |

| Net-Lbs-Hr | 1,225 | 1,453 | |||

| Avg Ram Speed (IPM) | 18.2 | 20.9 | |||

| 7" Press (2000 UST) | |||||

| 25% Percentile | Median | 75% Percentile | 90% Percentile | ||

| Recovery | 77.0% | 80.2% | 82.1% | 83.4% | |

| Net-Lbs-Hr | 1,816 | 2,800 | |||

| Avg Ram Speed (IPM) | 16.8 | 20.7 | |||

| 8" Press (2700 UST) | |||||

| 25% Percentile | Median | 75% Percentile | 90% Percentile | ||

| Recovery | 76.4% | 80.5% | 83.4% | 84.9% | |

| Net-Lbs-Hr | 2,707 | 4,011 | |||

| Avg Ram Speed (IPM) | 17.8 | 22.8 | |||

| 9" Press (3600 UST) | |||||

| 25% Percentile | Median | 75% Percentile | 90% Percentile | ||

| Recovery | 72.8% | 76.4% | 80.1% | 81.4% | |

| Net-Lbs-Hr | 3,138 | 8,337 | |||

| Avg Ram Speed (IPM) | 13.1 | 17.4 | |||

| 10" Press (4000 UST) | |||||

| 25% Percentile | Median | 75% Percentile | 90% Percentile | ||

| Recovery | 70.9% | 76.2% | 78.2% | 81.% | |

| Net-Lbs-Hr | 3,185 | 4,009 | |||

| Avg Ram Speed (IPM) | 14.3 | 20.8 | |||

| 12" Press (5200 UST) | |||||

| 25% Percentile | Median | 75% Percentile | 90% Percentile | ||

| Recovery | 68.4% | 73.1% | 75.8% | 76.2% | |

| Net-Lbs-Hr | 5,106 | 6,374 | |||

| Avg Ram Speed (IPM) | 16.4 | 22 | |||

| 14" Press (5700 UST) | |||||

| 25% Percentile | Median | 75% Percentile | 90% Percentile | ||

| Recovery | 72.0% | 77.5% | 80.8% | 81.9% | |

| Net-Lbs-Hr | 7,770 | 14,431 | |||

| Avg Ram Speed (IPM) | 24.7 | 25 | |||

Increasing pounds per hour by 1% = $50,000 to $100,000 annual savings and saved press time (reduced downtime)

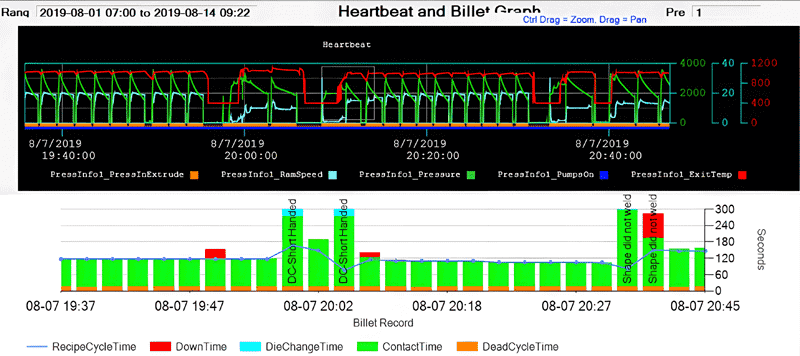

The Aluminum Extrusion Process Analysis service we provide for our North Carolina clients begins with a process audit and then development of a plan going forward based on the audit results. The audit will be a detailed analysis and establishment of baseline metrics based on observations and meeting with team members at your North Carolina aluminum extrusion facility.

Data Collection Documentation

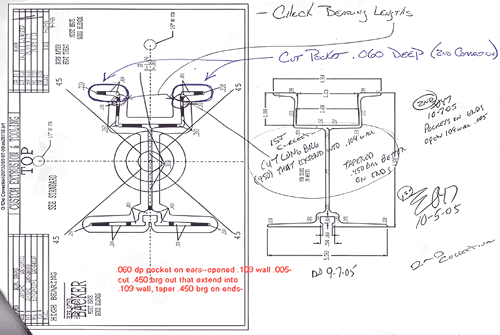

For aluminum extrusion dies at your North Carolina company that need repair, the data and feedback is sent back to suppliers. Working together, the actual results and repairs are documented. For clarity, pictures of noses and samples, and actual repairs, must be saved on the server. All repairs must include electronic die design, pictures of noses, repairs, and front ends, and are collected in a specific "check sheet" or procedure which is used to document performance and repairs. By tracking this information and sending it back to the supplier, subsequent copies of aluminum extrusion dies used at your North Carolina aluminum extrusion company will perform at a higher level.

The difference between a good aluminum extrusion die design and a great die design are small details. Training employees at your North Carolina aluminum extrusion company to do a periodic die design review with suppliers based on the family of parts is critical.

Here is how our team at JEL Enterprises handles new aluminum extrusion dies for North Carolina aluminum extrusion facilities:

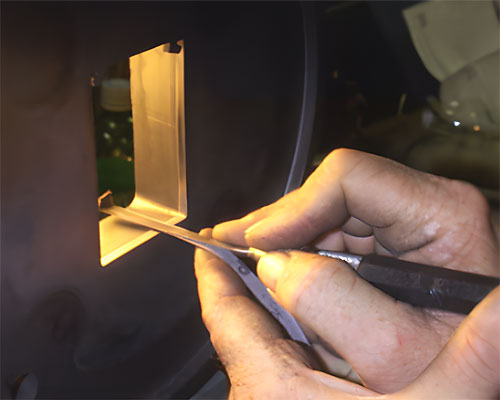

Die Technicians Polishing Dies

Die Technicians Polishing Dies

The key to training aluminum extrusion employees at your North Carolina company is checks and balances to understand if the training was effective. This can be achieved by observing aluminum extrusion operators doing their job, as well as understanding the job description and skills matrix, and verifying job expectations. These help us determine the type of training that needs to be done at your North Carolina aluminum extrusion company. We also have many training documents available.

Our employee evaluation and training for North Carolina aluminum extrusion companies includes:

Call JEL Enterprises at 609-321-5283, or email us, to find out how we can improve the productivity and profitability of aluminum extrusion processes at your North Carolina aluminum extrusion company.